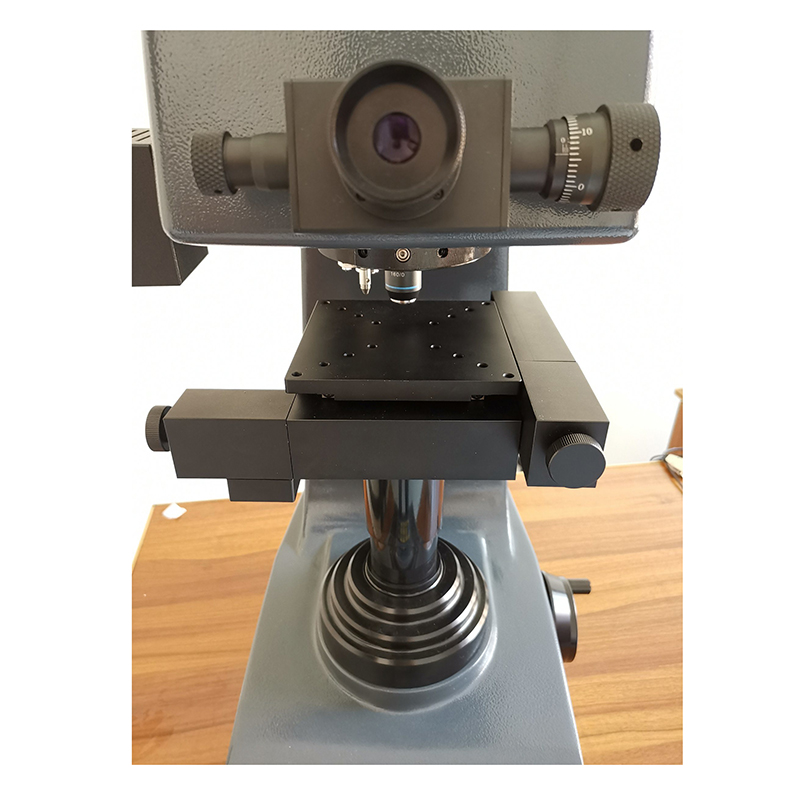

ZwickRoell has introduced the DuraVision universal hardness testing machine, which is a flexible solution that has a load range from 0.3kgf to 3,000kgf for tests on many different materials and component geometries.

Universal hardness testing machines are designed to accommodate hardness testing according to Brinell, Vickers, Rockwell and Knoop principles. To cover all of these test methods, a tester must offer a wide load range, which is where the DuraVision is able to meet customers’ needs. Durometer

Hardness testing not only applies to the determination of material characteristics in terms of hardness and forming processes, but it is also used for quick and effective testing during production processes to ensure that the material meets specific requirements and behaves optimally according to its intended application. ZwickRoell points out its range of universal hardness testing equipment ensure reliable test results in the laboratory, as well as in raw production environments.

The various models of the DuraVision range are software-controlled universal hardness testers with automated closed-loop load application and fully automatic test point evaluation. These advanced technology software-controlled instruments accommodate a variety of functions, including the use of templates, user defined specimen tooling, high resolution camera systems and electronically controlled load application. The fully automatic instruments can also be used to create a wide range of hardness curves and hardness mapping.

Another significant benefit of these universal testers comes from the addition of a revolving tool changing system, which facilitates speedy changeover between individual test methods.

The universal testing machines test in accordance with international industry standards, including ISO 6506, ASTM E10 (Brinell), ISO 6507, ASTM E384, ASTM E92 (Vickers), ISO 6508, ASTM E18 (Rockwell), ISO 4545 (Knoop), DIN 51917 (carbon testing), as well as ISO 2039 (plastics testing).

Will joined Fastener + Fixing Magazine in 2007 and over the last 15 years has experienced every facet of the fastener sector - interviewing key figures within the industry and visiting leading companies and exhibitions around the globe.

Will manages the content strategy across all platforms and is the guardian for the high editorial standards that the Magazine is renowned.

Don't have an account? Sign Up

Digital Hardness Tester Signing up to Fastener + Fixing Magazine enables you to manage your account details.